Innovation and sustainability in plastic injection

Innovation and sustainability in plastic injection:

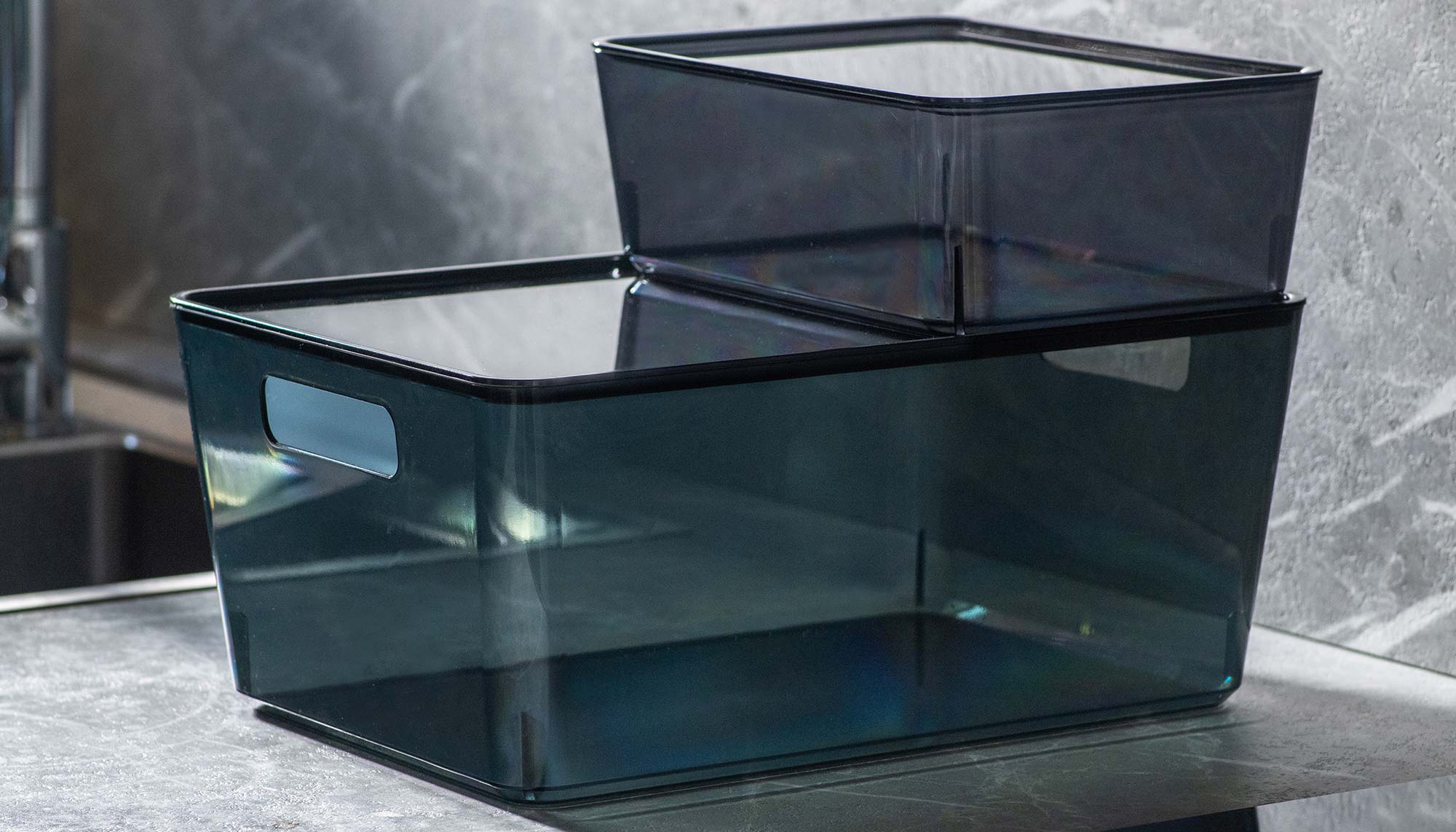

Pezzutti è uno specialista leader nello stampaggio ad iniezione di materie plastiche: con una lunga e consolidata esperienza nello stampaggio ad iniezione di componenti tecnici industriali, di prodotti complessi anche assemblati, fino ai prodotti d'arredo per la casa, l'ufficio e i prodotti per il mercato consumer. Siamo in grado di tradurre le vostre idee in un prodotto sostenibile ed efficiente

SCOPRI PEZZUTTI GROUP

Sustainable

Innovative

Ideazione,

Realizzazione,

Automazione del prodotto

Skills

I nostri numeri

0

Addetti

0

SQM area coperta

>0 mld

di componenti prodotti

>0

Presse ad iniezione

Sostenibilità

Sostenibilità

Pezzutti è fortemente impegnata nella riduzione degli impatti ambientali e climatici, contribuendo a mantenere pulito il pianeta. Per rispettare l’ambiente Pezzutti ha fatto e continua a fare ingenti investimenti in un sistema produttivo innovativo, all’avanguardia e sostenibile, ed è fortemente orientata all’utilizzo di plastiche riciclate post-consumo e post-industriali

Sostenibilità & ESG

MERCATI

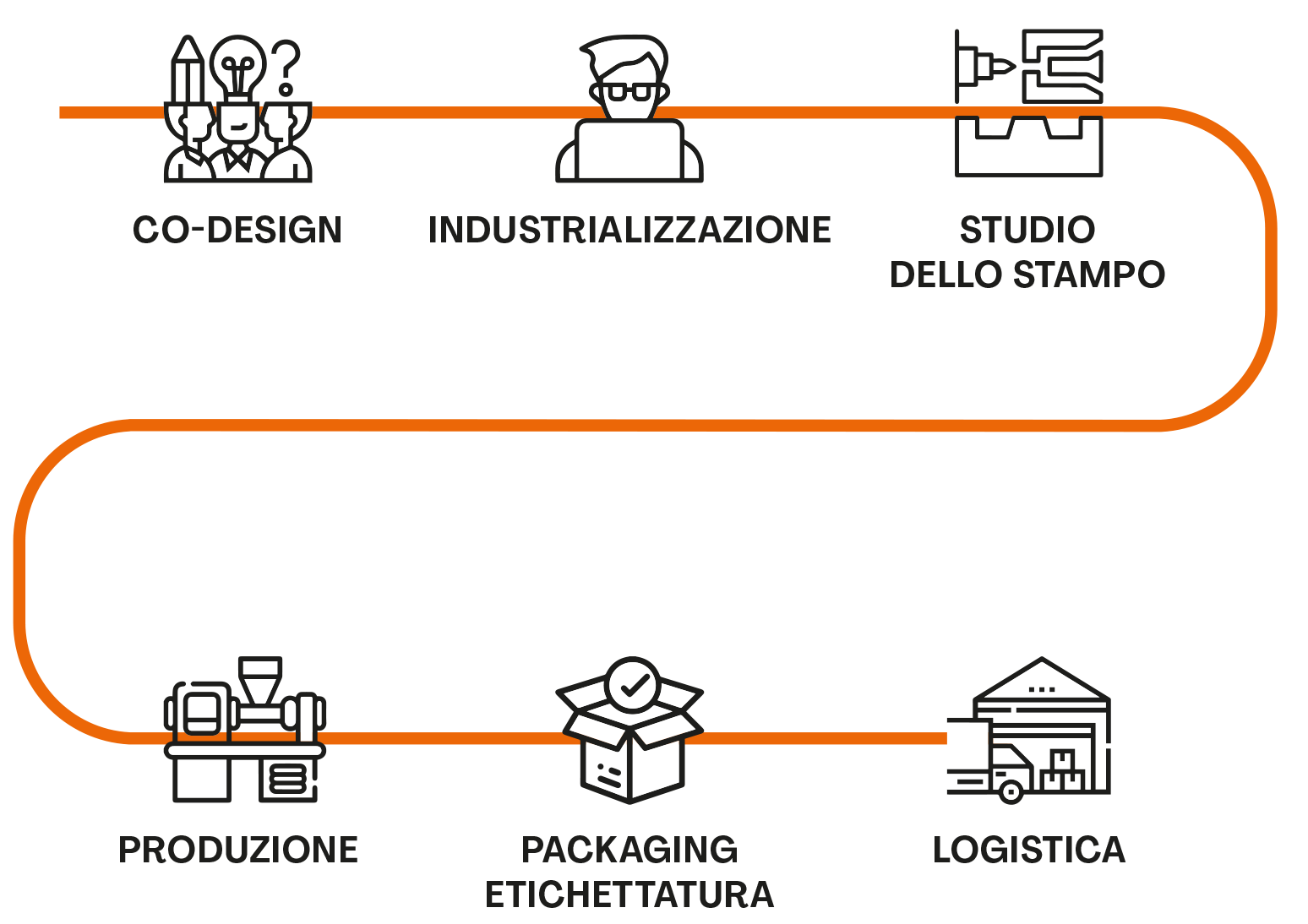

Pezzutti Group è un partner strategico nell'ideazione, co-design, costruzione di stampi, sviluppo e produzione, anche in serie, di prodotti personalizzati e finiti, realizzati in materiali polimerici e tecnopolimeri.

Scopri i mercati in cui lavoriamo:

Certificazioni

A completa disposizione

Rimaniano a tua disposizione per qualsiasi informazione sui nostri prodotti.

CONTATTACI